DSM Engineering Plastics recently opened its expanded $5 million research and technology center in the Detroit suburb of Troy, Michigan.

The opening of the Troy Research & Technology Center strengthens DSM Engineering Plastics’ product development and application development capabilities in North America, and will enable it to collaborate more closely and efficiently with its customers.

DSM Engineering Plastics has occupied 31,550 square feet of space formerly leased by Bally’s Total Fitness. The space which once held a dance studio, locker rooms, a boxing studio, shower rooms and a common exercise area has been converted by KIRCO and KIRCO MANIX into a Class A mixed use space for DSM Engineering Plastics.

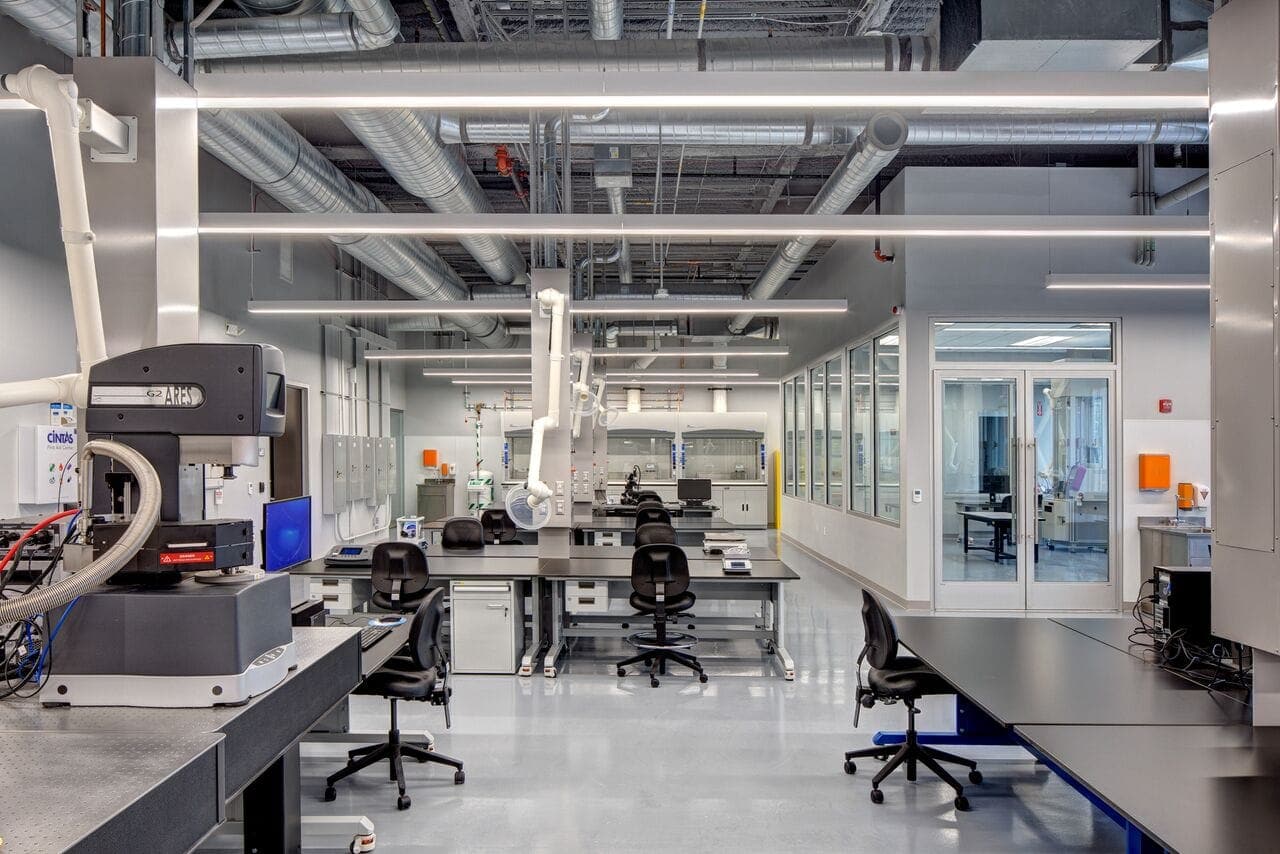

The new state of the art facility utilizes sustainable design elements and contains both open and closed office spaces, five large conference rooms that are convertible to one large conference space, and a lab space to be used for automotive plastics research and technology development.

UNIQUE BUILDING ELEMENTS

- Barrel vaulted skylight

- Large central staircase with glass railing accented by natural light from the vaulted ceiling

- Open, daylight filled collaborative work spaces

- Newly located European style lobby

- Mezzanine level collaboration area

- Contemporary European interior design features

- Covered parking with direct entry into the building

- Research & development lab area for future use

In addition, DSM is dedicating part of the lab to application testing in partnership with its customers. It also will develop novel test set-ups to drive a better understanding of the performance of DSM materials under field conditions.

The lab has additional floor space available to allow for increasing capacity of its current testing activities, and for introducing further capabilities, including flammability testing and secondary operations such as plastic welding.

SOME OF THE NEW FACILITY’S FEATURES INCLUDE:

- Broad range of mechanical testing capabilities

- Analytical techniques including microscopy

- Extensive testing capabilities on aging and chemical resistance of materials

- Physical material testing, including rheology and thermal analysis

- 3D printing capability to enable rapid prototyping

Related Projects

Location: Troy, MI

Size: 31,550 Square Feet

Market(s):

- Corporate Real Estate

- Lab/R&D

- Office & Headquarters

Awards:

Troy Chamber of Commerce’s Best of Troy Award